Views from above: Gary Works (U.S. Steel), Gary, IN, USA

It’s no secret that Climate TRACE uses satellites to identify and observe source activity — and then correlate that activity with emissions estimates. But what do the satellites actually “see”? And how do we translate activity observations into emissions numbers? In this series, Views From Above, we’ll unpack these questions, one asset at a time.

What is it?

ASSET NAME: Gary Works (U.S. Steel)

SECTOR / SUBSECTOR: Manufacturing - Steel

COALITION SECTOR LEAD: TransitionZero

LOCATION: Gary, IN, USA

DESCRIPTION: Located on the south shore of Lake Michigan and operational since 1908, Gary Works was once the largest steel plant in the world. It remains the largest facility of U.S. Steel, one of the biggest steel producers in North America. According to Climate TRACE data, it was the steel industry’s largest source of GHG emissions in North America for 2021.

High-level observations of emissions-causing activities

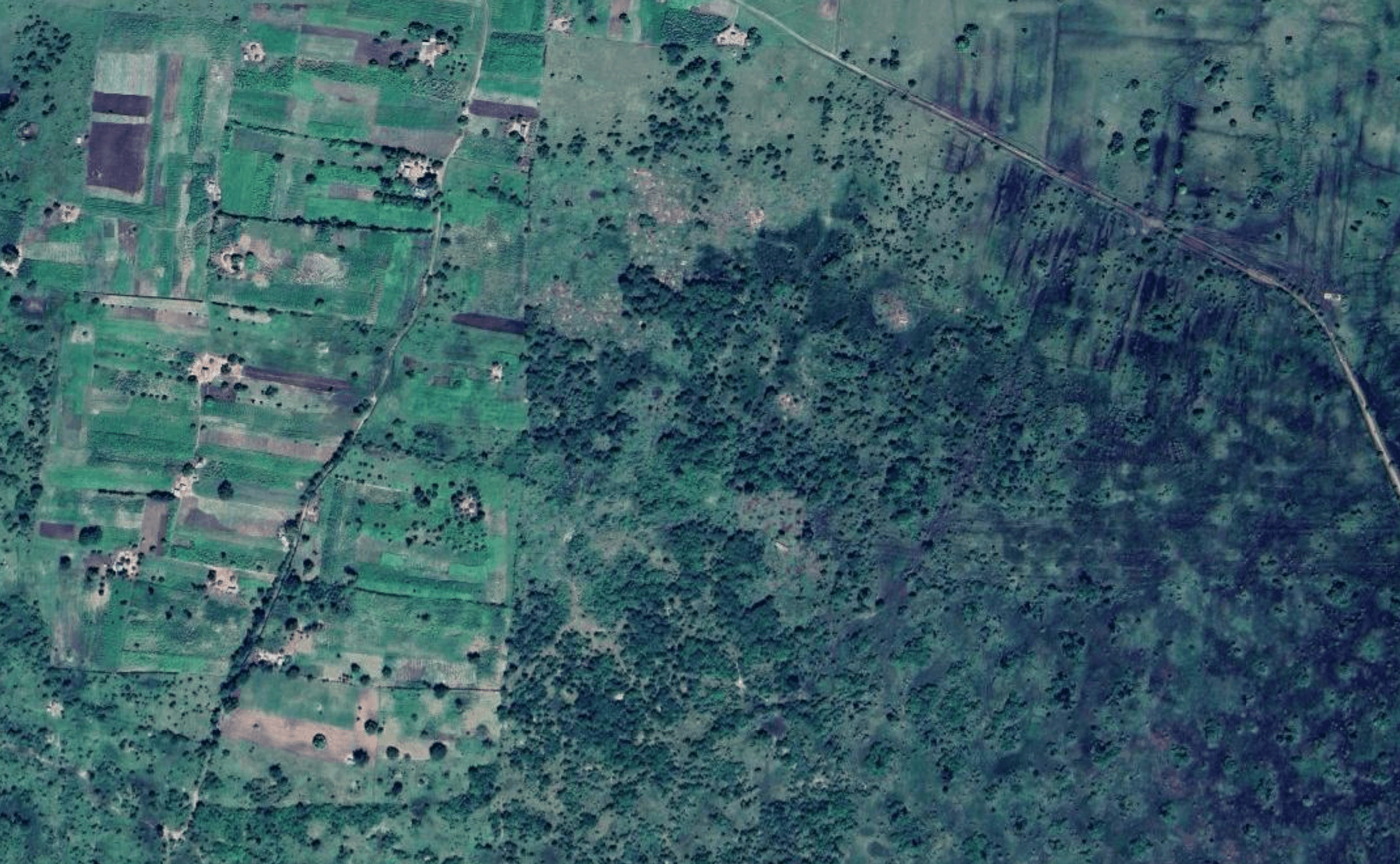

At the beginning of 2020, Gary Works had four blast furnaces in operation. Satellites could plainly “see” this activity via its heat signature, as captured by the short-wave infrared (SWIR) wavelength bands of Sentinel-2A/B and Landsat-8/9 satellites. Bands 11 and 12 are especially useful for detecting hotspots.

By the beginning of May 2020, due to the COVID-19 pandemic, three of its four blast furnaces had ramped down. This is evident in the much “quieter” heat signature from satellite imagery during that time period.

Ongoing monitoring of specific, high-interest areas

Once we identified relevant high-activity regions at Gary Works, we further isolated them algorithmically into more-specific areas known as sub-assets. These defined regions tell the Climate TRACE algorithms where to “look” on an ongoing basis. Plus, as we develop more-detailed insights into those sub-assets, we can associate them with relevant, specific emissions factors. For Gary Works, the monthly value of each sub-asset is determined by taking the average activity value of each pixel within its boundary.

Associating observed activity with relevant emissions factors

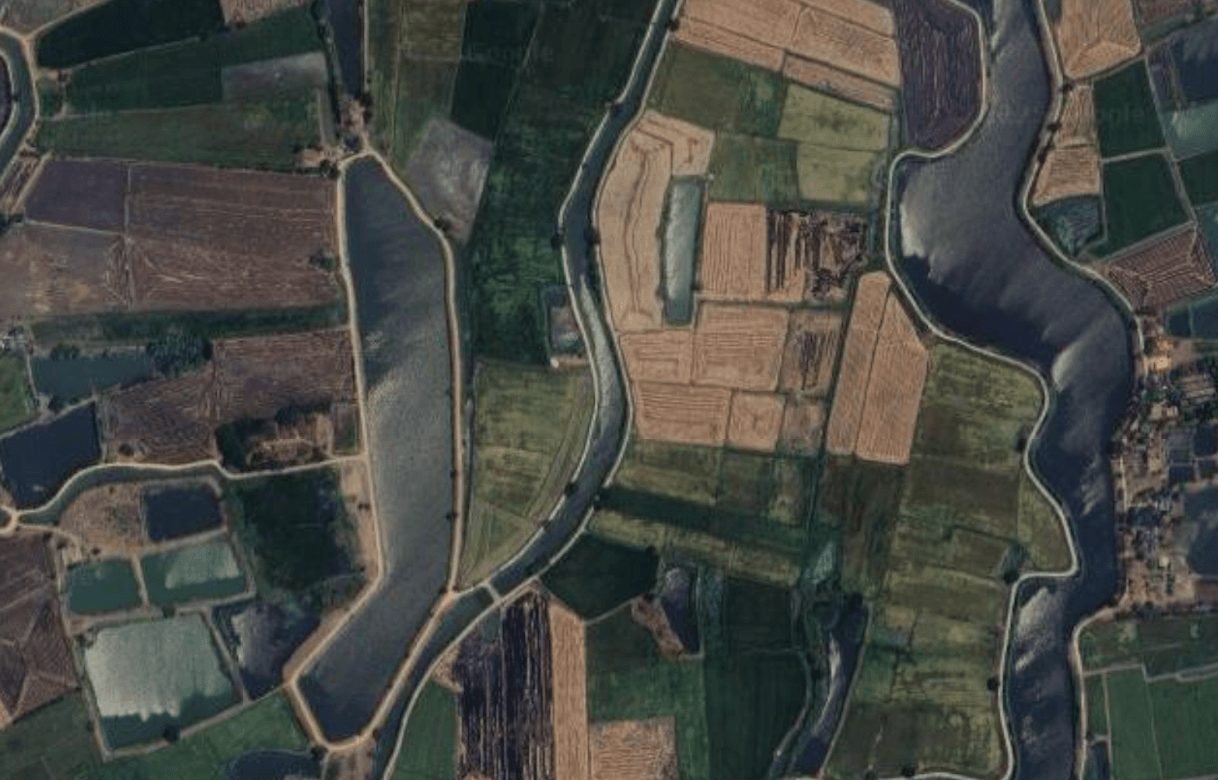

The sub-assets at Gary Works equate to three common features of steel plants, each of which has its own emissions factor:

— Blast furnace: A large, vertical furnace used in the production of iron and steel. Here, a mixture of iron ore, coke, and limestone is exposed to high-temperatures. Coke reacts with oxygen in the iron ore, producing carbon monoxide (CO) and carbon dioxide (CO2).

— Basic oxygen furnace: A large, vertical steelmaking furnace used for converting liquid iron from a blast furnace into steel. Here, CO2 emissions primarily result from the combustion of carbon in the molten iron.

— Slag pit: This is where slag, a mixture of impurities and non-metallic remnants from blast furnaces, is directed. It flows here to cool and solidify, making it easier to handle and dispose of, but during the cooling process, slag releases CO2 as a byproduct.

Producing quantified emissions estimates for the observation period

When we compare pre-pandemic steel production and GHG emissions at Gary Works during Q1 2020 to during-pandemic numbers in Q2 of that same year, as expected, the Climate TRACE data shows both a drop in production as well as a drop in associated emissions. Each declined about 25%. Steel production and emissions remained low through the balance of 2020, before rebounding to pre-pandemic levels in 2011.

You can read more about TransitionZero’s steel sector methodology here.