RPL Jamnagar: the world’s largest oil refinery

It’s no secret that Climate TRACE uses satellites to identify and observe source activity — and then correlate that activity with emissions estimates. But what do the satellites actually “see”? And how do we translate activity observations into emissions numbers? In this series, Views From Above, we’ll unpack these questions, one source at a time. In this edition, we spotlight India’s RPL Jamnagar Refinery.

Updated 25 June 2025: Climate TRACE data previously estimated RPL Jamnagar's 2022 emissions at 32.38 million tonnes CO2e 100yr. More-recent validation of the refinery's capacity resulted in a downward revision of historical and ongoing emissions estimates for this asset. The updated estimate for RPL Jamnagar's 2022 emissions based on Climate TRACE data release 4.3.1 is 19.76 million tonnes. It remains the world's top-emitting refinery.

What is it?

**—Source name:**RPL (Reliance Petroleum Limited) Jamnagar Refinery

—Sector / subsector: Fossil Fuel Operations / Oil and Gas Refining

**—Location:**Jamnagar, Gujarat, India

The RPL Jamnagar refinery is currently the largest oil refinery in the world. Overall, the entire complex includes an area of more than 7,500 acres and has a crude processing capacity of 1.4 million barrels per day — more than double that of Marathon’s Galveston Bay refinery in Texas, the largest in North America (631,000 barrels per day). Owned by Reliance Industries, the refinery was commissioned in July 1999 and expanded in 2008. Today, RPL Jamnagar processes an array of crude oils and produces petroleum products, including liquefied petroleum gas (LPG), propylene, naphtha, gasoline, jet / aviation turbine fuel, superior kerosene oil, high-speed diesel, sulfur, and petroleum coke. According to Climate TRACE data, RPL Jamnagar was the world’s highest-emitting refinery in 2022, emitting 19.76 million tonnes of CO2e that year, equal to the world's 2nd- and 3rd-largest emitters combined.

Observing emissions-causing activities

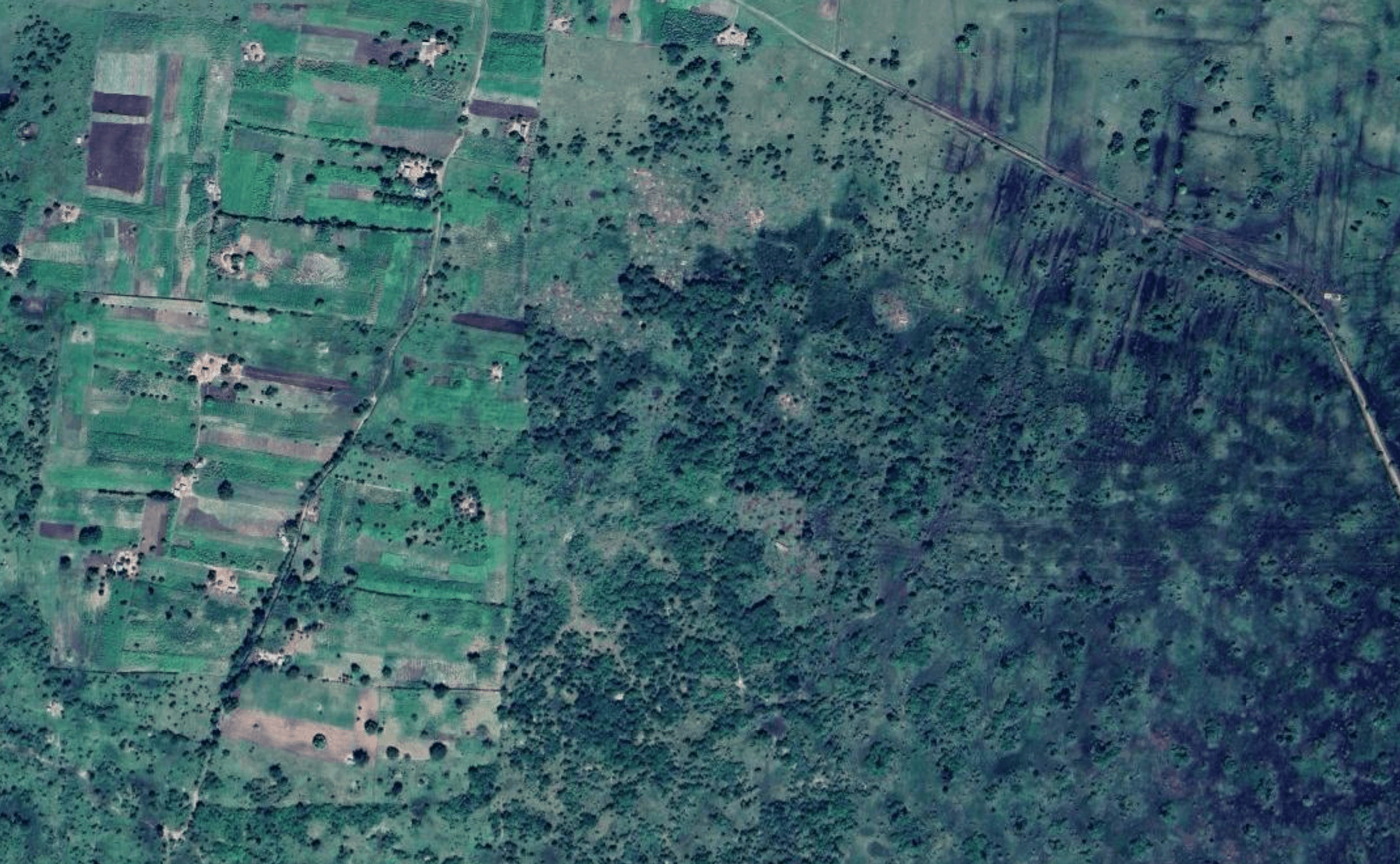

In total, the RPL Jamnagar facility covers a land area similar to nearly eight New York Central Parks and is more than 10 times the land area of the City of London, the British capital’s famed historic financial district.

Climate TRACE coalition sector experts approach the emissions estimation work with a combination of public ground truth data and independent data validation strategies. When available, satellite imagery helps improve confidence in identification of emissions-causing activities.

For detail on RPL Jamnagar, the team uses a mix of public data from the refinery owner and reputable independent public sources, such as the Energy Institute and the International Energy Agency (IEA). Spot visual assurance checks of satellite images help confirm the presence of certain emissions-causing sub-assets and activities, such as areas of petroleum coke production and storage as well as sulfur recovery.

Using these visual inputs, we can zoom in to see, in red, where most direct emissions are likely to occur, based on sector expert evaluation of equipment layout seen in satellite views. The yellow areas represent areas where some emissions are likely to be produced.

Associating observed activity with relevant emissions factors

We then input this site configuration data and other observed data, such as crude oil input type and petroleum coke storage areas, into academically developed, industry-tested models, including the University of Calgary’s open source PRELIM refinery model, which the oil and gas industry and policymakers also widely use. This modeling gives us our emissions factors (i.e., tonnes of greenhouse gas emitted per barrel of oil or gas refined).

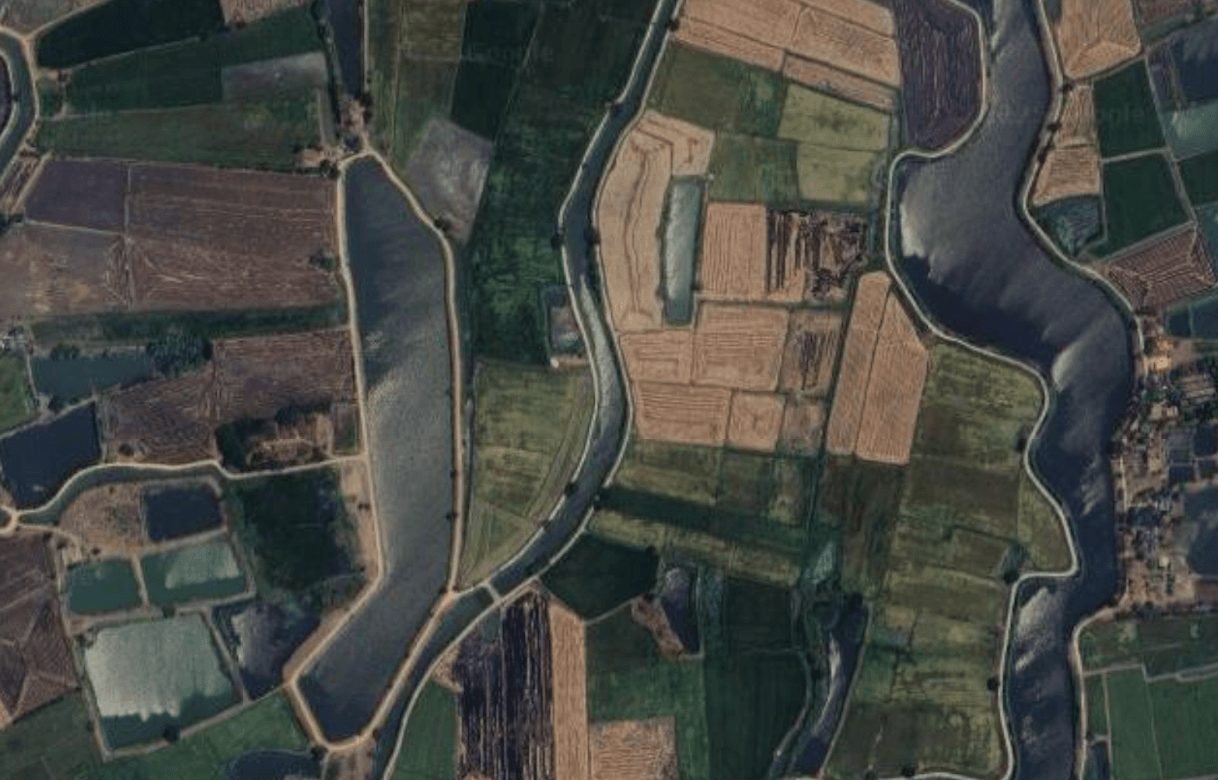

As a part of the refining process, RPL Jamnagar stores petroleum coke in the areas surrounded by the orange boxes we see below. These areas indicate that the refinery uses petroleum coke production process units also known as cokers, which are high-emitting refinery equipment. This means that RPL Jamnagar is a deep conversion refinery, or a refinery that has a unit to transform tar-like heavy bottom residues into coke and lighter products. For this reason, TRACE sector experts use a deep conversion configuration in the PRELIM refinery model to estimate emissions factors for these highly polluting units.

Translating reporting period activity into emissions estimates

Finally, TRACE sector experts multiply best-fit emissions factors by estimated activity levels for each emitting site — which accounts for max refinery crude processing capacity, time, and the percentage of capacity used — to get final emissions estimates. Since the 2020 pandemic, RPL Jamnagar's emissions have ranged between 18.78 and 20.24 million tonnes annually, peaking in 2023.

Ready to dig into more? Explore Climate TRACE data for RPL Jamnagar yourself here. Or explore other assets of interest on the interactive Emissions Map.

image credits**Satellite imagery via Google Earth. Chart / data visualization via Climate TRACE.